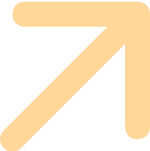

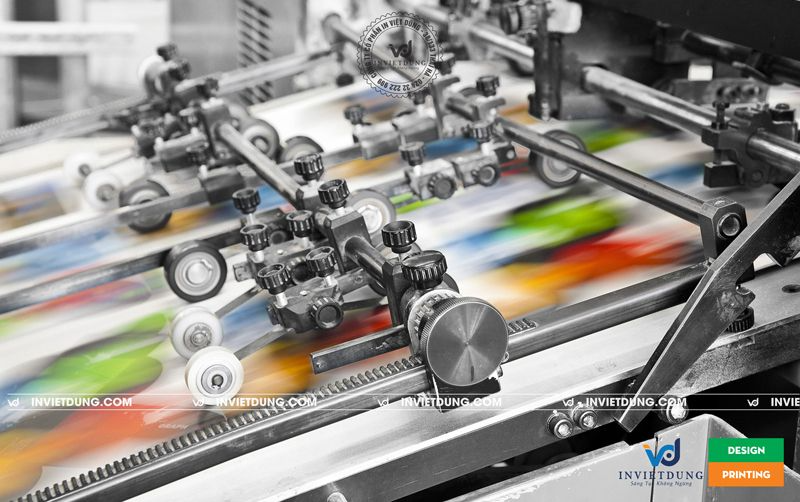

Offset printing is a printing technique in which inked images are transferred (offset) onto rubber sheets (referred to as offset plates) before being pressed onto paper. Nowadays, offset printing technology is widely used by printing companies in Hanoi.

Offset printing is a flat printing technique. In offset printing, the printing elements are displayed on the zinc plate through the plate-making process. In this process, the printing elements attract ink, while the non-printing elements attract water. Subsequently, the inked zinc plate is pressed onto rubber sheets (also known as offset plates). The offset plate is then pressed onto the printing paper surface, and the ink adheres to the paper’s surface, creating the desired printed image.

Zinc Plate (Plate): A metal zinc tube, with printing elements attracting ink and non-printing elements attracting water.

Rubber Cylinder: A system of cylinders carrying offset rubber sheets. This rubber cylinder rotates in the opposite direction to the zinc plate. The printing elements on the zinc plate are pressed onto the surface of the rubber cylinder. The rubber cylinder presses the image and printing elements onto the printing paper surface.

Paper Feeding Unit: Responsible for pulling paper from the table, supplying paper at the input.

Ink Supply Unit: Consists of a system of multiple tubes supplying ink from the ink tray to the zinc plate.

Dampening Unit: Includes dampening rollers moistened with a solution containing gum arabic to dampen the printing plate.

Transfer Unit: A system of springs, shafts, etc., transports paper through the rubber cylinders to receive the printing elements.

Paper Exit Unit: A system of trays and bars that eject and stack printed sheets into a paper stack. Additionally, there is a powder spray system to instantly dry the printed sheet to prevent smudging or ink smearing.

Offset printing is the most modern and widely used printing technology in commercial printing today.

High-quality, sharp, and clean color image printing.

Applicable to various printing materials and surfaces.

Plate making is easy and faster with computer support.

Longer lifespan of printed plates because they do not directly contact the printing surface.

Cost-effective for large quantities.

High-speed production for large quantities.

While the quality is excellent, offset printing is more cost-effective for larger quantities. Printing small quantities or just a few copies can be expensive due to the inherent nature of this technology.

Most widely used printing technology in commercial printing.

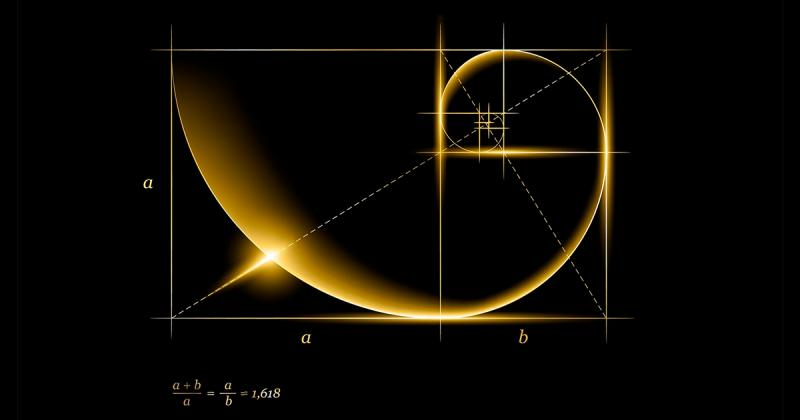

Frequently used in office and advertising printing, such as books, newspapers, catalogs, brochures, etc.

Economically beneficial for medium and large quantities.

Can print on various material surfaces: paper, plastic, PVC, etc.

Offset printing is the most popular printing technology in commercial printing due to its significant advantages. In Việt Dũng Printing Company in Hanoi, with a direct production offset printing workshop, the printing system is constantly improved to provide customers with sharp, color-accurate, and evenly colored printed products at the best cost.

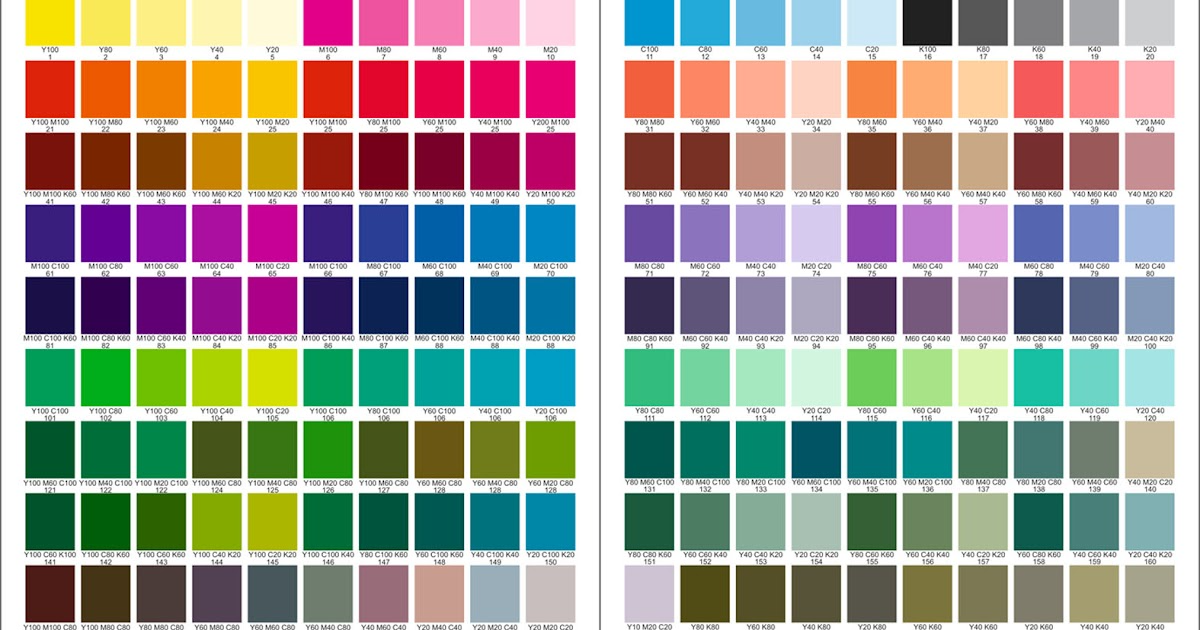

To ensure the quality of offset printing products and avoid defects, the plate-making process on a computer is extremely crucial. Plate-making involves processing design files, arranging printed sheets, laying out pages, and configuring color separations such as process color CMYK. Plate-making typically utilizes specialized design software like Illustrator, Corel Draw, Adobe Acrobat, etc., and the final file is output as a PDF.

Utilizing Computer to Film (CTF) technology, digital data from the computer is converted into analog data on film through film recording machines. There are usually four films representing the colors C (Cyan), M (Magenta), Y (Yellow), and K (Black). These films are black and white.

After film development, the films are adhered to printing plates. These plate-adhered films are then placed in a plate exposure machine. Based on the principle of photosensitivity, areas without printing elements will erode. Printing elements, where light cannot pass through or only partially penetrates, will erode or partially erode.

Note: Nowadays, with more advanced technology, manufacturers have developed machines that directly print images onto printing plates, known as Computer to Plate (CTP) machines.

To ensure the quality of offset printing products and avoid defects, the plate-making process on a computer is extremely crucial. Plate-making involves processing design files, arranging printed sheets, laying out pages, and configuring color separations such as process color CMYK. Plate-making typically utilizes specialized design software like Illustrator, Corel Draw, Adobe Acrobat, etc., and the final file is output as a PDF.

Utilizing Computer to Film (CTF) technology, digital data from the computer is converted into analog data on film through film recording machines. There are usually four films representing the colors C (Cyan), M (Magenta), Y (Yellow), and K (Black). These films are black and white.

After film development, the films are adhered to printing plates. These plate-adhered films are then placed in a plate exposure machine. Based on the principle of photosensitivity, areas without printing elements will erode. Printing elements, where light cannot pass through or only partially penetrates, will erode or partially erode.

Note: Nowadays, with more advanced technology, manufacturers have developed machines that directly print images onto printing plates, known as Computer to Plate (CTP) machines.

Printing plates are loaded onto the printing machine on cylindrical rollers. After adjusting the color registration to align images on the printing plates, the printing process begins. Cylindrical rollers with attached printing plates are immersed in ink. Printing elements (non-eroded parts on the printing plate) pick up ink, while non-printing elements (eroded parts on the printing plate) attract water. The roller with the attached plate rotates and presses onto another rotating roller with rubber sheets (also known as offset sheets), transferring the ink from the offset sheets to the paper surface. This process creates the desired printed image.

Mount the printing plate onto the plate assembly.

Feed ink into the ink tray, evenly distribute ink on the ink transfer system.

Feed paper, printing material, into the paper tray.

Adjust the printing plate for color registration, adjust the rubber roller pressure.

Receive the printed sheet and post-process.

32x43

36x52

39x54

43x65

52x72

54x79

65x86

72x102

79x109

1-color

2-color

4-color

5-color

Offset Printing Machine

Offset Printing Machine

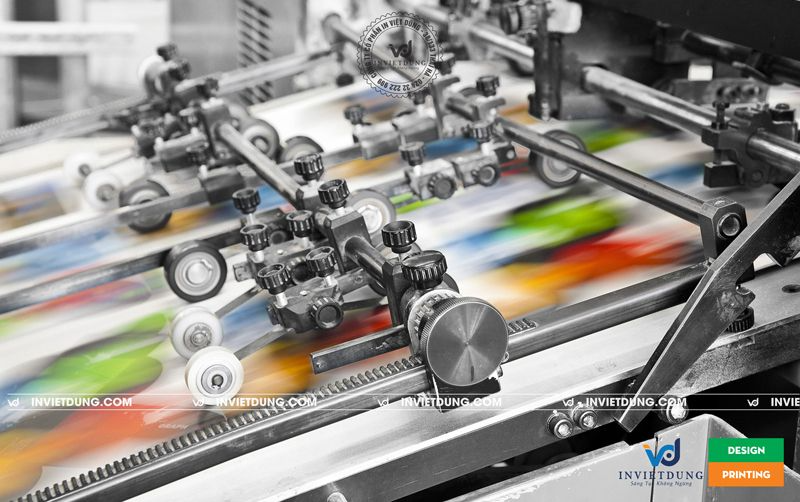

In simple terms, the Golden Ratio is a mathematical ratio. It is abundantly present in nature, and when applied in design, it represents aesthetics, embodying the natural balance of creation. But have you ever wondered what the Golden Ratio truly is and how to use it to enhance your designs?

When it comes to print advertising, understanding the appropriate sizes is crucial for creating high-quality and engaging materials. This article will guide you through the considerations and benefits of adjusting print sizes to achieve satisfactory results.

In lighting design, a solid understanding of the applicable standards is the key to creating harmonious and efficient lighting spaces. With the continuous development of technology and modern design trends, mastering crucial design standards is not only necessary but also a determining factor for the impression of a space. Let’s explore and grasp these standards together to create innovative lighting spaces that touch every human emotion.

Everything in the office should be arranged, organized, and selected to achieve evenness and balance in a certain proportion. This principle is also applied to many small office design models.

In interior design, many consumers mistakenly perceive lighting design as simply selecting different types of lamps, determining wattage, choosing styles, and matching colors with the interior. However, in reality, this is an inaccurate concept.

In the field of fashion retail, a fashion store front typically has 3 mannequins, IKEA arranges items like a home, … It’s not by chance that products are placed the way you see them. Each position in the store is carefully calculated to keep customers there longer, which translates to spending more. The job demands both creativity and a business mindset, and it belongs to visual merchandisers. In this article, find out how visual merchandising works, its impact on brands and revenue.

Surely you have come into contact with printed publications such as desk calendars, flyers, standees, etc. So have you ever wondered how these publications are created or who is behind these publications?

Offset printing is a printing technique in which inked images are transferred (offset) onto rubber sheets (referred to as offset plates) before being pressed onto paper. Nowadays, offset printing technology is widely used by printing companies in Hanoi.

A beautiful piece of work, no matter how aesthetically pleasing, loses more than half of its value if not adorned with suitable colors. In printing, the criteria for color are even more critical. Therefore, the selection of printing colors always takes the most contemplative time in designs. The printing color palette is diverse and mystical. Let’s explore it through the following article.

Event organization is one of the popular and highly competitive industries in the job market that attracts the interest of many young individuals. It is also a crucial aspect of the advertising, communication, and entertainment services industry.

Before launching a new product, the first thing a business needs to do is market research to understand customer needs, current market trends, and competitors. This will help the business identify target markets and develop appropriate marketing strategies to promote its product.